Hydraulic pumps are essential components in various industrial applications, including construction machinery and agricultural equipment. Standco offers a range of hydraulic solutions, notably the YCY Piston Pump, which exemplifies the performance and reliability expected in hydraulic systems.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Hydraulic pumps convert mechanical energy into hydraulic energy by moving fluid from a reservoir into a hydraulic system. They perform two primary functions:

Hydraulic pumps can be classified into two main categories:

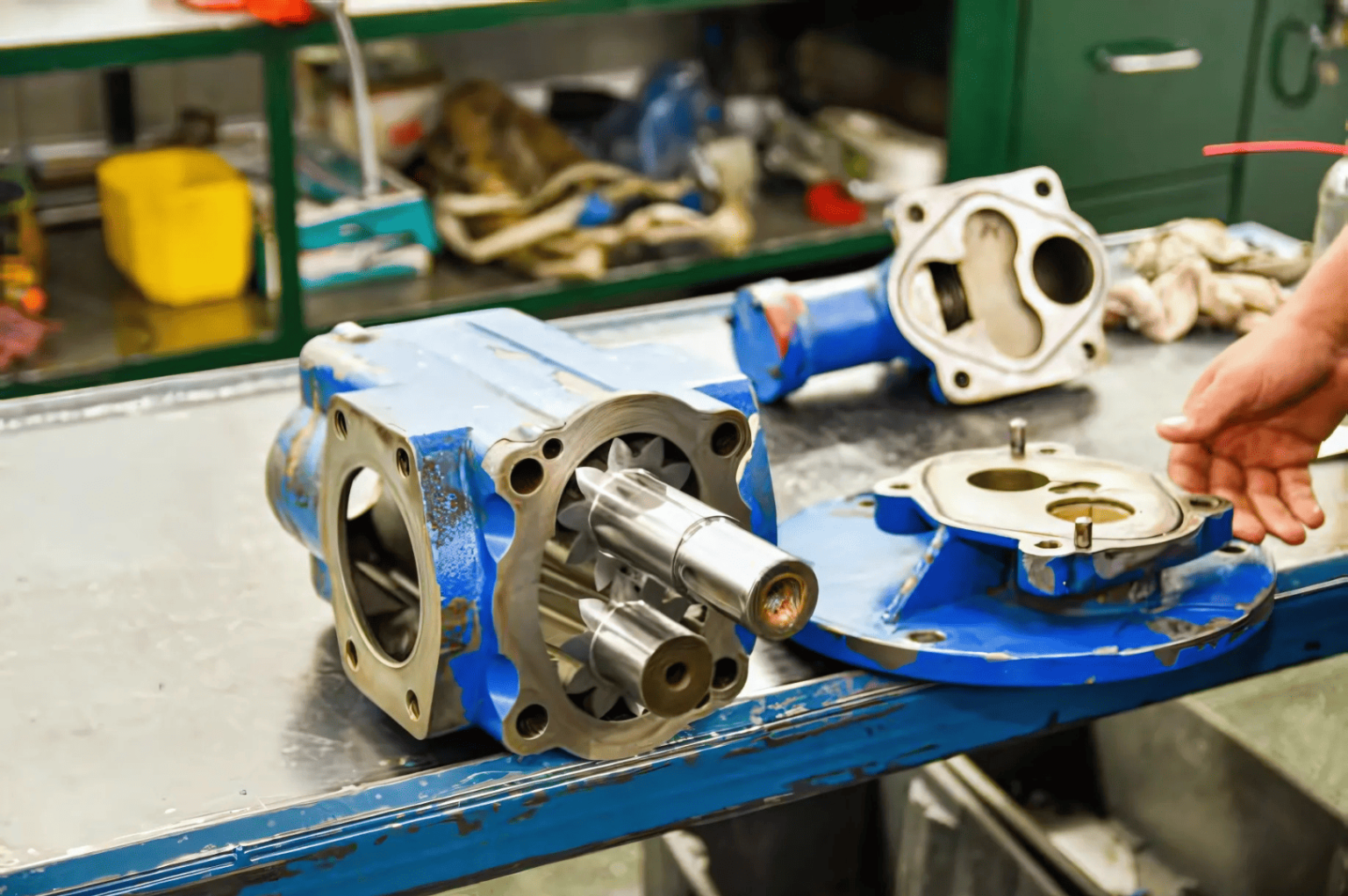

1. Positive Displacement Pumps: These pumps deliver a fixed volume of fluid with each cycle, ensuring consistent flow rates. They are further divided into gear pump, vane pump and piston pump.

Simple and reliable, suitable

for low-pressure applications.

Offer moderate efficiency

and flexibility.

Provide high efficiency and pressure capabilities, ideal for demanding applications.

2. Non-Positive Displacement Pumps: These are less common in hydraulic systems but can be useful in specific scenarios where variable flow is necessary.

When choosing a hydraulic pump, the following main factors should be prioritized:

1. Flow Rate Requirements

Determine the volume of hydraulic fluid needed for your application, measured in liters per minute (L/min) or gallons per minute (GPM).

2. Pressure Ratings

Ensure the pump can generate the necessary pressure for your system without risking damage.

3. Fluid Compatibility

Verify that the pump materials are compatible with the hydraulic fluid regarding viscosity, temperature, and chemical composition.

4. Pump Type

Choose the appropriate type of pump (gear, vane, or piston) based on your application’s specific needs.

5. Efficiency

Look for pumps with high efficiency ratings to reduce energy consumption and operational costs.

6. Operating Environment

Consider environmental factors such as temperature and exposure to dust or moisture that may affect pump performance.

7. Maintenance Requirements

Opt for a pump that is easy to maintain to prolong functionality and minimize downtime.

8. Budget Constraints

Factor in both initial costs and total cost of ownership, including maintenance and energy consumption over time.

Understanding hydraulic pumps is crucial for anyone working with hydraulic systems. By investing in reliable hydraulic solutions, companies can enhance operational efficiency and reduce downtime. For tailored solutions or further inquiries about Standco’s products, feel free to reach out for expert assistance.

Information

My Account

Get In Touch

Contact Us

Working Hour

Location