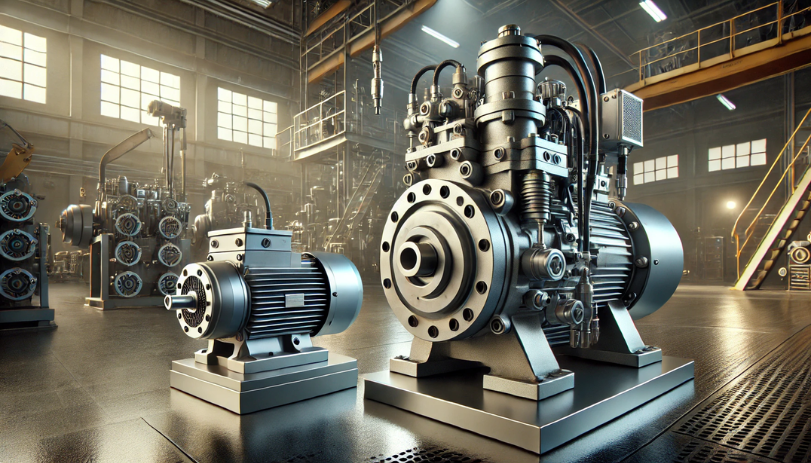

Choosing between a hydraulic pump and an electric motor can be challenging. Both have unique strengths that suit different types of applications. Here’s a breakdown of key factors to help you decide which one might be the best fit for your needs.

Hydraulic pumps generate high power from a compact unit, making them well-suited for heavy lifting and high-force applications found in industries like construction and manufacturing. By contrast, electric motors provide steady, reliable power for applications with moderate power demands.

Electric motors generally offer superior energy efficiency, converting a higher percentage of energy input into usable power. This makes them a preferred choice for companies focusing on energy savings. Hydraulic pumps, while often less efficient, are evolving with new variable-speed models designed to improve overall energy usage.

Hydraulic pumps require regular maintenance to keep the system running smoothly. This includes checking fluid levels, inspecting seals, and monitoring pressure levels. Electric motors, with fewer moving parts and no fluid management requirements, tend to be easier and cheaper to maintain over time.

Hydraulic pumps typically have a higher upfront cost, but they offer excellent long-term value for high-force applications due to their durability. Electric motors, with a lower initial cost, are a cost-effective option for applications that don’t require substantial force.

Electric motors are more eco-friendly, with no fluids to manage and minimal waste. Hydraulic systems, while improving with new eco-friendly fluids and better sealing, still pose environmental risks due to potential leaks.

| Features | Hydraulic Pump | Electric Pump |

|---|---|---|

| Power Output | High power, ideal for heavy-duty tasks | Steady performance for moderate power needs |

| Energy Efficiency | Less efficient, though newer models are improving | Generally high efficiency |

| Maintenance | Requires regular fluid checks and part inspections | Lower maintenance, fewer moving parts |

| Costs | Higher initial cost, better for high-force tasks | Lower upfront cost, good for low-force tasks |

| Environmental Impact | Potential fluid leaks, newer eco-friendly options available | Environmentally friendly, no fluid waste |

| Best Application | Construction, manufacturing, automotive | Automation, electronics, light industry |

Conclusion

The choice between a hydraulic pump and an electric motor depends on your specific requirements. Hydraulic pumps excel in heavy-duty, high-force applications, while electric motors are preferred for their efficiency, lower maintenance, and eco-friendliness in moderate power applications.

At Standco, we offer robust hydraulic pumps designed to meet demanding industrial needs. For help selecting the best solution for your application, contact us or visit our website for expert guidance.

Information

My Account

Get In Touch

Contact Us

Working Hour

Location